Puffed Snacks Line with Double Screw Extruder (higher capacity)

Extruded direct expanded snacks are typically puffy, crispy or crunchy cereal or starch “finger foods” that come in a variety of shapes and sizes and which are textured and often coated to make them convenient, tasty and fun. They are eaten at all times of the day and can be sweet or savory. Snacks are eaten for pleasure, but increasingly, they need to be healthier as well. Saibainuo’s twin-screw systems enable snack makers to meet all these criteria and meet ever-changingconsumer demand, enabling them to enhance their brands locally and internationally.

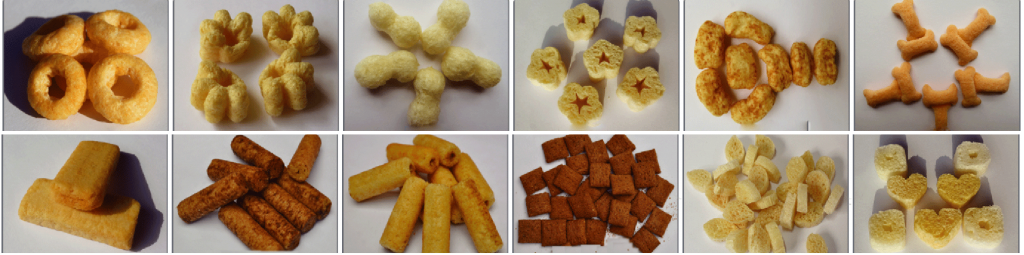

Snacks come in all shapes and sizes:

Core filling co-extrusion:

We added co-extrusion attachment, we can do core filled puffed snacks with different filling options.

We can further change the cutter and shaper to make different products like, pillow, long tube, short tube, square tube products.

Core Filling Co-Extrusion:

If you make bigger size like above with chocolate core filling, you can do as a single pack snacks even with chocolate enrobing options!

Besides, with some additional optional equipment, your twin screw puffed line can be turned into following Production Line

Breakfast Cereal and Corn Flakes Production Line

Textured/Fibre Soya Protein Food Production Line

Nutritional Artificial Rice Production Line

Puffed rice production line

Nutritional Powder Production Line

Modified Starch Production Line

Bread Crumbs Production Line

Pet Food Processing Line

Breakfast Cereal Processing Line

Breakfast cereal processing line can use corn, rice, oat, other grain powder, and also some healthy nutritional ingredients like vitamin as raw materials to produce kinds of breakfast cereal snacks which can be eaten with milk as instant food.

Breakfast cereal processing line can use corn, rice, oat, other grain powder, and also some healthy nutritional ingredients like vitamin as raw materials to produce kinds of breakfast cereal snacks which can be eaten with milk as instant food. After coated with sugar syrup or honey, the cereal will be tasted well and aet like leisure snacks directly. The breakfast cereal shapes are like ring, ball, star, stick, and others changed by different moulds. This processing line can also produce other puffed snacks. It is muti-functional line which is the beat choice for clients.

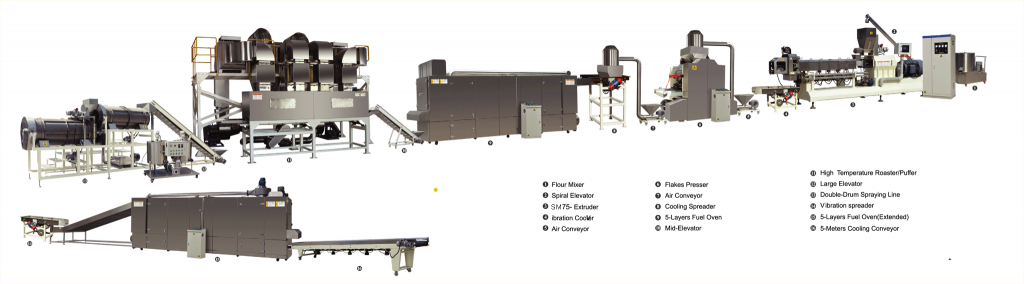

Production Flow:

Flour Mixer → Screw Elevator → Double-screw Extruder????? →Elevator → Dryer →Elevator → Coating Line → Vibrating Spreader → Elevator → Dryer → Cooling Conveyor

Corn Flakes Processing Line

This corn flakes processing line can not only produce the corn flakes but also breakfast cereal products by adjusting some assistant machines.

This corn flakes processing line can not only produce the corn flakes but also breakfast cereal products by adjusting some assistant machines. The main raw material is corn powder in 60-80 mesh, and other grain powder or some nutritional ingedients, like vitamin. The raw materials will be cooked well in the extruder by twin screw rotating under high temperature and pressure. After the high temperature roaster, the flakes will be bublled and smelt well. The coating line can make the syrup or honey on the flakes surface. This corn flakes processing line is characteristics of simple opeation, reasonable structure, low consumption, and high efficiency, which make it the best choice for medium factory.

Production Flow:

Flour Mixer → Screw Elevator → Double-screw Extruder → Air Conveyor → Flaking Machine → Elevator → Dryer → Elevator → Roaster → Elevator → Coating Line → Vibrating Spreader → Elevator → Dryer → Cooling Conveyor

Bread Crumb Processing Line

With some Modification in machine and process, Following Bread Crumb can be made

Flake Bread Crumb Processing Line

The Flake crumb processing line can produce the bread crumb in small flake shape which is newly popular in the market.

The Flake crumb processing line can produce the bread crumb in small flake shape which is newly popular in the market. It is widely used to coat on the fried shrimp, chicken, and other meat to obtain a vary crispy and savory texture as well as unique and attractive fried foods’ golden color presentation.

For this Flake crumb processing line, the machines required are like following:

Flour Mixer → Screw Elevator → Double-screw Extruder → Vibrating Spreader →Elevator → Dryer → Cooling Conveyor

This flake shape can be cut directly from the extruder no need the grinder machine. So it is well accepted by the buyers for the lower cost and simple production process

Needle Japanese Bread Crumb Processing Line

This Needle Japanese Panko Bread Crumb Processing Line can use wheat flour, corn powder, and rice powder as raw materials to produce the Panko bread crumb in needle shape.

This Needle Japanese Panko Bread Crumb Processing Line can use wheat flour, corn powder, and rice powder as raw materials to produce the Panko bread crumb in needle shape. Such crumbs are light and crispy which are popular to used for fried chicken, burger patty, sea foods (shrimp, fish), onion rings, etc. to obtain a vary crispy and savory texture as well as unique and attractive fried foods’golden color presentation.

For this Needle Japanese Panko Bread Crumb Processing Line, the machines required are like following:

Flour Mixer → Screw Elevator → Double-screw Extruder → Cutter →Elevator → Crushed /Grinder→ Conveyor →Sifter → Elevator → Dryer → Cooling Conveyor

Granular American Bread Crumb Processing Line

This Bread crumb processing line is researched and developed on the basis of international advanced technology.

This Bread crumb processing line is researched and developed on the basis of international advanced technology. The performance and quality have reached the highest domestic level of the same line. This line changes the traditional process for producing bread crumb. From mixing materails, extruding, cutting, drying to finished products are done in one automatic line. The extruded bread crumbs are light and crispy with innovative shapes, like small rings, crescent, stars, balls, granule, and flakes. They are widely used as food coating additives on the surface of frying food, such as, fried chicken, burger patty, sea foods (shrimp, fish), onion rings, etc. to obtain a vary crispy and savory texture as well as unique and attractive fried foods’golden color presentation.

For this Gruanular American bread crumb processing line, the machines required are like following:

Flour Mixer → Screw Elevator → Double-screw Extruder → Cutter →Elevator → Crushed /Grinder→ Conveyor →Sifter → Elevator → Dryer → Cooling Conveyor