Deposited Lollipop Production Line with advanced SERVO technology

Features:

- Capacity:

For lollipop: (based on 10g ): approx. 300kgs/h

10g x 25strokes/min x 20 cavities x 60min=300kgs/h - Micro-film cooking

- The PLC controller is separated out of the cooker to prevent the hot wet steam doing the harmful effects on the PLC and electronic parts

- The automatic regulator valve with electric positioned can automatically control the supply of steam to cooker via a more stable vapor pressure

- Servo-drive designed depositor: Three axis servo control ensures the complete control over the depositing process

- Auto Flavor & color dosing system

- Bigger and stronger mould-carrier chains

- Double jacket connecting pipes, valves and mixing system and hot water generation system

- All contact parts made of food grade Stainless-Steel

Products can be made from this line

Standard One/Two color deposited Lollipop with different flavor options

One/Two color stripe deposited Lollipop

Moulds can be made according to the candies samples provided by the customer.

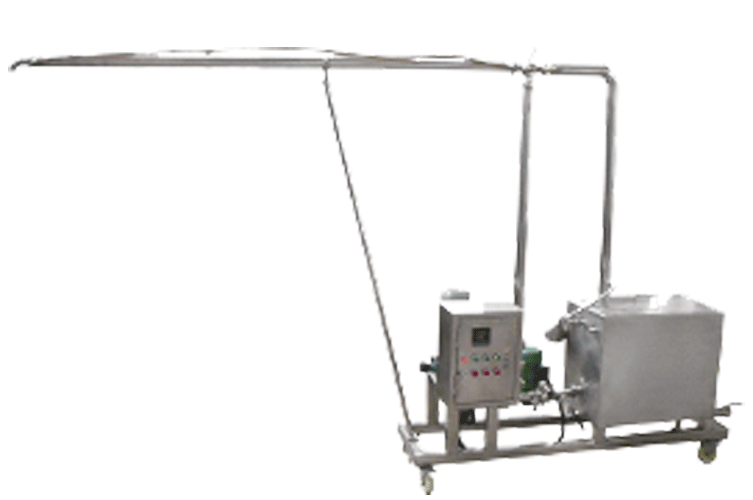

Depositing and cooling section

By some little modification more products can be made from this line

Chocolate Center- Filling Machine for Center filled Candy